Optical and Mechanical Properties of Lithium Aluminosilicate Glass-ceramics

DOI:

https://doi.org/10.61343/jcm.v1i01.5Keywords:

Lithium Aluminosilicate glasses, TEM, FESEMAbstract

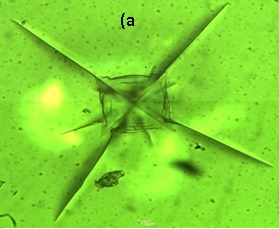

Lithium aluminosilicate glass-ceramics has many uses in high-tech applications. Beta quartz or spodumene solid solution phase in the Li2O-Al2O3-SiO2-P2O5 glass system has been precipitated by controlled heat-treatment of the parent glass. These glasses prepared by melt-quench technique. High transparency (>80%) in the visible wavelength range has been observed in the material by UV-VIS-NIR spectrometry. FTIR spectra indicated the presence of Si-O as well as Al-O bonds in the glass-ceramics. The LAS glass ceramics showed moderate flexural strength (~80 MPa) and young’s modulus (~50 GPa). Microstructural characterization of the heat-treated glass ceramics by FESEM and TEM showed nano-crystalline spherical particles of 30-40 nm, which provided a rationale for its high transparency and good mechanical properties that may open up possibilities for newer applications.

References

G. H. Beall, “Design and Properties of Glass-Ceramics,” Annu. Rev. Mater. Sci., 22, 91–119 (1992).

A. Jacobsen and T. Marx, “Applications of the Glass-Ceramic Zerodur”; pp. 198–211 in Low Thermal Expansion Glass-Ceramics. Edited by H. Bach. Springer–Verlag, Berlin, Germany, 1995.

G. H. Beall and L. R. Pinckney, “Nanophase Glass-Ceramics,” J. Am. Ceram. Soc., 82 [1] 5–16 (1999).

L. Arnault, M. Gerl and, and A. Rivi`ere, “Microstructural Study of Two LAS-type Glass-ceramics and Their Parent Glass,” J. MAT. SC.,35, 2331-45 (2000).

U. Schiffner and W. Pannhorst, “Nucleation in a Precursor for a Li2O–Al2O3–SiO2 Glass-Ceramic, Part 1: Nucleation Kinetics,” Glastech. Ber., 60 [6], 211–21 (1987).

J. M. Jewell, M. S. Spress, R. L. Ortolano, and J. E. Shelby, “Effect of Heat-Treatment Temperature on the Properties of a Lithium Aluminosilicate Glass,” J. Am. Ceram. Soc., 74 [1], 92–7 (1991).

L. Barbieri, C. Leonelli, T. Manfredini,C. Siligardi, A. B. Corradi, P. Mustarelli, and C. Tomasi, “Nucleation and Crystallization of a Lithium Aluminosilicate Glass,” J. Am. Ceram. Soc., 80 [12] 3077–83 (1997).

B. Karmakar, P. Kundu, S. Jana, and R. N. Dwivedi, “Crystallization Kinetics and Mechanism of Low-Expansion Lithium Aluminosilicate Glass-Ceramics by Dilatometry,” J. Am. Ceram. Soc., 85 [10] 2572-4 (2002).

P. W. McMillian, Glass-Ceramics, 2d ed. Academic Press, New York, 1978.Holland Press, New York, 1984.

G. H. Beall and D. A. Duke, “Glass-Ceramic Technology”; pp. 404-44 in Glass Science and Technology, Vol. I, Glass Forming Systems. Edited by D. R. Uhlmann and N. J. Kreidl. Academic Press, New York, 1983.

G. H. Beall and R. C. Damon, “Glass-Ceramics”; pp. 21-35 in Encyclopaedia of Physical Sciences and Technology, Vol. 6. Academic Press, New York, 1987.

A.M. Hu, M. Li and D.-L. Mao, “Crystallization of Spodumene-Diopside in the LAS Glass ceramics with CaO and MgO Addition,” J. Therm. Anal. Calorimetry, 90[1], 185–9 (2007).

A. M. Hu, M. Li, and D. L. Mao, “Growth Behavior, Morphology and Properties of Lithium Aluminosilicate Glass Ceramics with Different Amount of CaO, MgO and TiO2 Additive,” Ceram. Inter.,34, 1393–7 (2008).

Y. Himei, T. Nagakane, K. Fukumi, N. Kitamura, J. Nishii, A. Sakamoto, and K. Hirao, “Thermo-optic Properties of B2O3 doped Li2O-Al2O3-SiO2 Glass-ceramics,” J. Non-cryst. Solids, 354, 3113-9 (2008).

A. Arvind, Rakesh Kumar, M.N. Deo, V.K. Shrikhande, and G.P. Kothiyal, “Preparation, Structural and Thermo-mechanical Properties of Lithium Aluminum Silicate Glass–ceramics,” Ceramics International, 35, 1661–6 (2009).

A. Makehima, Y. Tamura, and T. Sakaino, “Elastic Moduli and Refractive Indices of Aluminosilicate Glasses Containing Y2O3, La2O3, and TiO2,” J. Am. Ceram. Soc., 61[5-6], 247-9 (1978).

L. Zhien, Y. Jianjun, X. Zhiyun, “The Interface, Microstructure and Mechanical Properties of CF/LAS Glass-Ceramic Composites,” J. Mat. Sc.,30, 399-404 (1995).

K. J. Anusavice and N-zheng Zhang, “Effect of Crystallinity on Strength and Fracture Toughness of Li2O-Al2O3-CaO–SiO2 Glass-Ceramics,” J. Am. Ceram. Soc., 80 [6] 1353–58 (1997).

An-Min Hu, Kai-Ming Liang, M. Li, Da-Li Mao, “Effect of Nucleation Temperatures and Time on Crystallization Behavior and Properties of Li2O–Al2O3–SiO2 Glasses” Mater. Chem. and Phys.,98, 430–3 (2006).

H. Anmin, L. Ming, and M. Dali, “Phase transformation in spodumene–diopside glass,” J. Therm. Anal. and Calorimetry, 84 [2], 497-501(2006).

Evans, A. G., Lawn, B. R., Marshall, D. B., “Elastic/plastic indentation damage in ceramics: the median/radial crack system,” Journal of the American Ceramic Society,63 [9-10], 574-581 (1980).

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright© by the author(s). Published by journal of Condensed Matter. This is an open access article distributed under the terms of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.