TGA and Thermal Kinetics of Raw Calotropis Procera Fiber Reinforced PF Composites

Sharma R1*, Joshi A2, Dimple3, Singh G4

DOI:10.61343/jcm.v1i01.6

1* Ritika Sharma, Department Of Physics, Govt Dungar College, Bikaner 334001, Rajasthan.

2 Akshay Joshi, Department Of Physics, Govt Dungar College, Bikaner 334001, Rajasthan.

3 Dimple, Department Of Physics, Govt Dungar College, Bikaner 334001, Rajasthan.

4 G P Singh, Department Of Physics, Govt Dungar College, Bikaner 334001, Rajasthan.

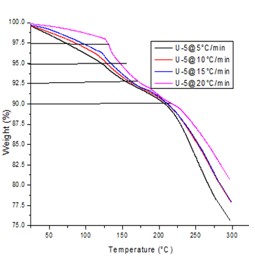

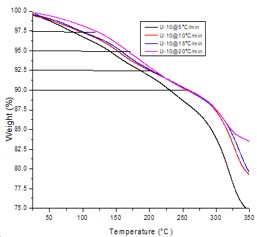

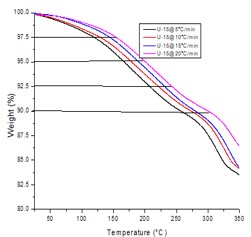

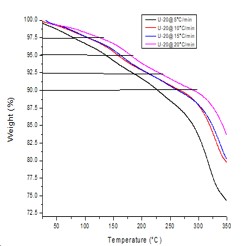

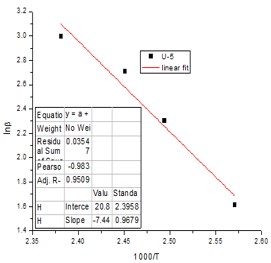

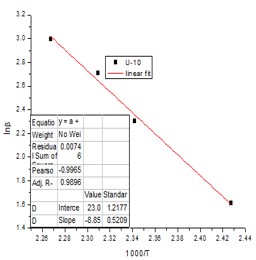

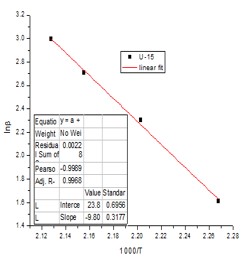

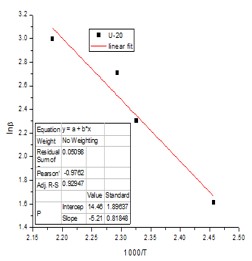

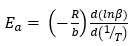

Natural fibre-reinforced composites are used in various structurally designed goods, from civil engineering to the production of automobiles, thanks to qualities like minimal density, a favourable aspect ratio, biodegradability, and ease of fabrication. The thermal behaviour of natural fibres and composites has also been researched. The thermal degradation kinetics characteristics of composites made with phenol formaldehyde resin and reinforced with untreated Aak fibre with varying fibre loads have been determined using thermogravimetric analysis (TGA). The Flynn-Wall procedure determined each component and composite material's precise apparent activation energy (Ea). Varying fibre load (5, 10, 15, 20 wt.%) was used to reinforce PF resin, and TGA was taken for all composite samples. By observing TGA data composite with 15 wt% fibre load shows maximum thermal stability, it can also be concluded that the thermal stability of prepared composites increases with increasing fibre load. After 15 wt%, it starts to decrease.

Keywords: Untreated Aak fibre, PF resin, TGA, Chemical kinetics for TGA

| Corresponding Author | How to Cite this Article | To Browse |

|---|---|---|

| , , Department Of Physics, Govt Dungar College, Bikaner 334001, Rajasthan, . Email: |

Sharma R, Joshi A, Dimple, Singh G, TGA and Thermal Kinetics of Raw Calotropis Procera Fiber Reinforced PF Composites. J.Con.Ma. 2023;1(1):29-33. Available From https://jcm.thecmrs.in/index.php/j/article/view/6 |

©

©  (1)

(1)