Synthesis of Multi Wall Carbon Nanotubes based Electronic Sensors for Internet of Things (IoT)

Bilal M1, Shama P2*

DOI:10.61343/jcm.v1i01.10

1 Muhammad Bilal, Department of Computer Science Engineering, Jamia Hamdard, New Delhi 110062, India.

2* Parveen Shama, Department Of Physics, Dpg Degree College, Gurugram 122004, Haryana, India.

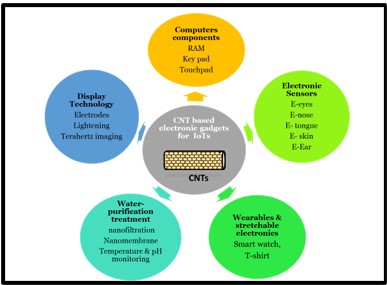

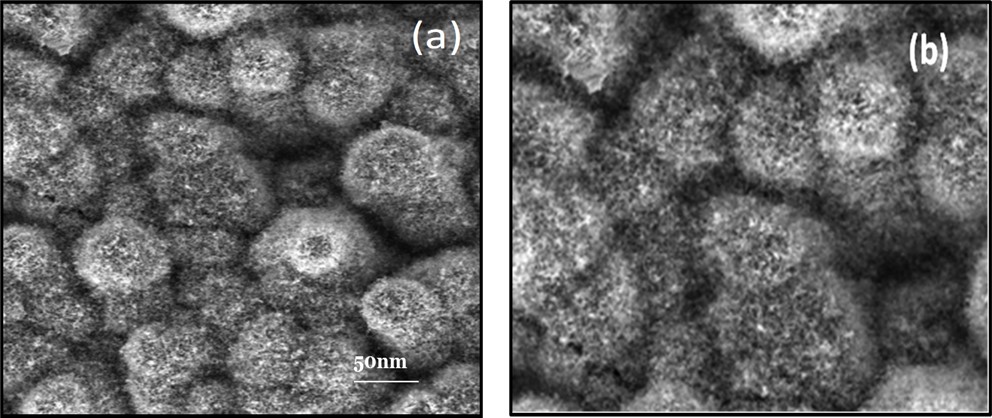

The Internet of Things (IoT) refers to advance devices other than computers that are connected to the Internet and can send and receive information. In every aspect of life, IoT is spreading at very high speed to change the whole lifestyle. IoT is a new architype that has modified traditional lifestyles into smart and high-tech ones and having revolutionized advancement. It is the notion of a ubiquitous computer environment in which custom-sized electronics are effortlessly implanted into common things. Electronic sensors at the heart of the IoT detect physical/environmental occurrences, translate these measurements into electrical signals, and wirelessly transfer the data for remote computation. The basic requirement for the active components of 5G communication and cloud computing encourage the technologist and researchers in applications of carbon nanotubes in electronic and digital devices. CNTs have demonstrated potential applications in digital electronics, sensing, remote sensing, artificial intelligence and the Internet of Things. In present study, we report the synthesis of Multi Wall Carbon Nanotubes (MWCNTs) by Chemical Vapour Deposition (CVD) at 600C on Zinc Oxide (ZnO) catalyst coated silicon substrate by thermal evaporation technique. As-grown MWCNTs are characterized by Scanning Electron Microscope (SEM). High density growth of MWCNTs have been confirmed by SEM image. Catalyst nanoparticles play very important roles in the decomposition of the hydrocarbon source and to provide nucleation site for growth of MWCNTs. High MWCNT density is required for IoT-based sensors with high performance, sensitivity, selectivity, and distant sensing. Because IoT not only provides services but also creates massive amounts of data. Hence, this study would be helpful for the next generation 5G communication and cloud computing stimulate to enhance living style.

Keywords: Multiwall Carbon nanotubes, Internet of things (IOT), Chemical Vapour Deposition, Scanning Electron Microscope

| Corresponding Author | How to Cite this Article | To Browse |

|---|---|---|

| , , Department Of Physics, Dpg Degree College, Gurugram 122004, Haryana, India. Email: |

Bilal M, Shama P, Synthesis of Multi Wall Carbon Nanotubes based Electronic Sensors for Internet of Things (IoT). J.Con.Ma. 2023;1(1):59-63. Available From https://jcm.thecmrs.in/index.php/j/article/view/10 |

©

©  Figure 1 (a) SEM image of as-grown MWCNTs on ZnO catalyst (b) at high magnification

Figure 1 (a) SEM image of as-grown MWCNTs on ZnO catalyst (b) at high magnification